The meat packing industry has evolved during the 21st century with significant technological advancements to meet consumer's demands. A recent drive for better sustainable, ethical and food safety standards, has added pressures to many meat-packing operations.

The meating packing industry in the UK is worth around £8 billion to £10 billion annually as of 2022/2023. This is a significant contribution to the national economy and to jobs, businesses, and consumers.

Our products can help streamline your packing processes and ensure that food safety standards are met. We have an abundance of plastic storage containers to optimise your meat-packing operations for the 21st century.

The Meat Industry Guide

The UK meat consumption has shifted from 2007 to 2022 with the forecast for 2027 to be stagnant for kilograms per capita. Over this period there has been a change in meat consumption with red meat (beef, lamb and pork) slowly declining due to socioeconomic factors. Despite this, poultry consumption has been more resilient during this period and has not seen an increase.

What is the Meat Industry Value Chain?

The value chain in the UK has gone through a period of uncertainty due to many recent factors including Covid-19, the economic crisis and political party changes. In 2022, it has been estimated that the value chain in the UK is worth around £9.5 billion and is set to grow by 1.6% over the next five years.

The value chain includes stringent processes and demanding budgets. Additional demands from consumers have pushed processes to be more refined and meet certain ethical and sustainable practices.

The value chain from livestock farming to consumers table includes:

1. Livestock Production

This will include breeding and raising livestock such as cattle, pigs, chickens, sheep and more so they are healthy, happy and can produce the best quality meat. In combination, you need to give them the correct amount of feed and supplements so your livestock is raised to the highest standards, for either supermarket's or consumers' demands. As society becomes more conscious of where their meat comes from, it is important to increase free range and organic supplies as this ethically fits more consumers' moral compass.

2. Transportation

The initial transportation of livestock to the slaughterhouse can be costly and occurs when livestock reaches market weight. There have been advancements in supporting livestock's happy lifestyles before slaughter and transportation is a priority in doing so.

3. Slaughter process

They have become more humane through the years and uphold strict laws that make sure that animals are slaughtered in the correct process. It can be broken down into a two-step process, stunning and sticking.

4. Packing for Distribution

This is an important process as it protects the meat from spoiling and ensures it is safe for human consumption. An animal transport certificate must be completed on every journey unless an exemption is met.

Packing materials must be suitable for food handling and withstand high-temperature sterilisation. This is important for making sure that meat is stored correctly and ready for transportation. There are two types of packing for meat, primary and secondary packing.

Primary packing includes fresh, frozen, vacuum-sealed and secure, this type of packing will protect meat from external environments and contamination. These will typically extend the shelf life of the meat and ensure that the expiry date is extended.

Secondary packing includes further packing that can bundle and bind products for bulk distribution. When storing, organising and distributing meat efficiently the correct plastic containers, crates and boxes can save you valuable time, and money and comply with stringent regulations.

Cold chain management is vital as its sole purpose is to protect the meat condition before consumption. Alison Handlings' secondary packing with regulatory primary packaging can protect the quality of your meat for suppliers.

How can Alison Handling support your meat packing and distribution?

At Alison Handling we have secondary packing that will help you be cost-effective and comply with legislation. Our secondary packing includes:

Bale Arm Crates

These are manufactured in food-grade polypropylene which is compliant with stringent food safety standards, and highly durable against general wear and tear of the meat packing industry. Their features include smooth internal surfaces that are easy to clean and stacked on top of each other without damaging the contents. They come in a variety of sizes and depths to help customise and organise your meat produce. The swing bar will minimise product movement and damage in transportation, and the optional perforated sides allow consistent ventilation.

Dolavs

The golden standard of plastic pallet boxes, as they come moulded in one piece, and are widely used across industries because of their versatility. Food production can benefit from their structural foam, easy-to-clean walls and corrosion-resistant design. We recommend Dolav boxes to those transporting heavy loads of meat from one location to another with minimal stress.

Most importantly you will be able to take advantage of its UV-resistant materials to protect your meat from sun exposure, and a range of temperatures that could cause dangerous bacteria to grow. Its dual walls will safely house your meat in transportation and ensure quality control remains high for the end consumer.

Pallets

It is a great way to move your meat without worrying about loads being too heavy, as it can withstand a static load of 5000kg, dynamic load of 1500kg, and racking load of 1000kg without breaking. This will help you transport and distribute your meat after the slaughter process with efficient timelines for your suppliers. The pallet boxes will increase your transportation processes and improve your lasting relationships with suppliers.

Commercial Waste Bins

Waste management can be time-consuming in the value chain due to health and safety standards needing to be met. Also, removing large amounts of waste requires large wheelie bins that can handle the load without breaking down or causing contamination. We supply a reliable range of wheelie bins that can help you give your business secure, safe and reliable waste management solutions.

They are made from HDPE and are easy to clean once used, this makes them efficient at waste management. We stock a range of colours to help you segment your waste, this will allow you to remove waste appropriately, safely and through the correct protocols. You can optimise your wheelie bins with extras, such as drop doors and forklift pockets that’ll reduce manual handling and improve employee productivity.

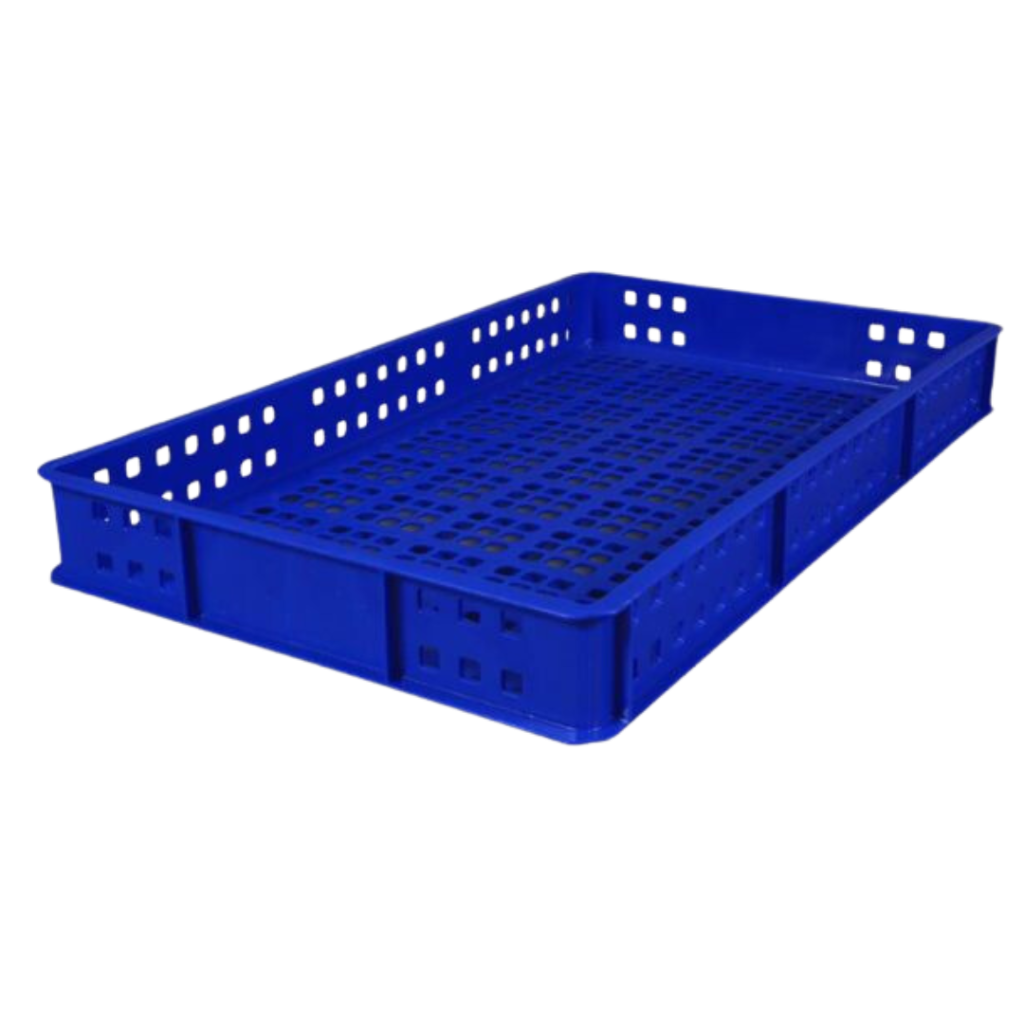

Stacking Containers

We stock a wide range of plastic stacking containers in a variety of sizes and colours that will help you store, organise and keep your meat ready for consumption. They come in a choice of standard sizes that will allow you to securely stack them in transportation. You can choose from perforated or solid to keep your meat at the correct temperatures. Each box comes with smooth surfaces that will make cleaning efficient and safe.

They are suitable for a range of temperatures (-30* to +80* degrees) allowing you to keep your meat protected so that no unwanted bacteria growth occurs in the cold value chain. These plastic containers give you quality control and keep your meat high quality.

We highly recommend these containers for those looking to improve the organisation of meat due to the range of colours they come in, whether it's sectioning out red meat, poultry and others, you can make sure that your value chain process is efficient and safe. Food standards are paramount and must be met, these stacking containers can make them easily achievable from temperature resistant, easy to clean, standard stacking sizes, perforated or solid and drop on lids for security.

Dollies

A great addition to your distribution process and handling of stacking containers. You can use these dollies with stacking containers to enhance the manoeuvrability of your meat around the slaughtering house, farm and distribution centres. It will cause less stress on your employees and reduce intensive labour. These dollies will take heavy loads off your employees and ensure their safety, minimising risks and enhancing quality. It's a simple solution to help streamline processes and improve employee satisfaction.

The Future of Meat Packing and Distribution

The future of the meat packing industry is up for debate as many people move away from meat consumption entirely, it's thought that in the UK 16% of the population are/will be on a meat-free type of diet in 2024.

A concerning impact of this decade-old trend is that it's cultivating several new jobs outside of the meat industry. It’s pushed forward a streamlined process, that upon ethical standards, our plastic containers can help you achieve both. Get in contact with Alison Handling today and stay ahead of the competition!